Once installed the load capacity of Cavidrain® Invert is equivalent to the strength of the concrete used.

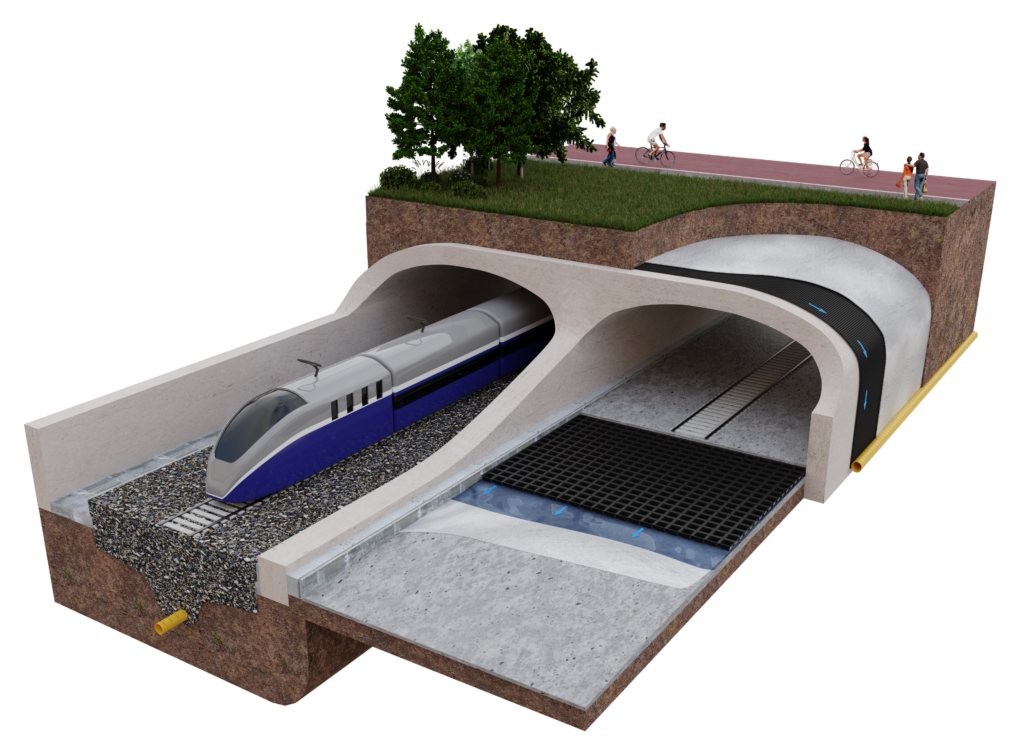

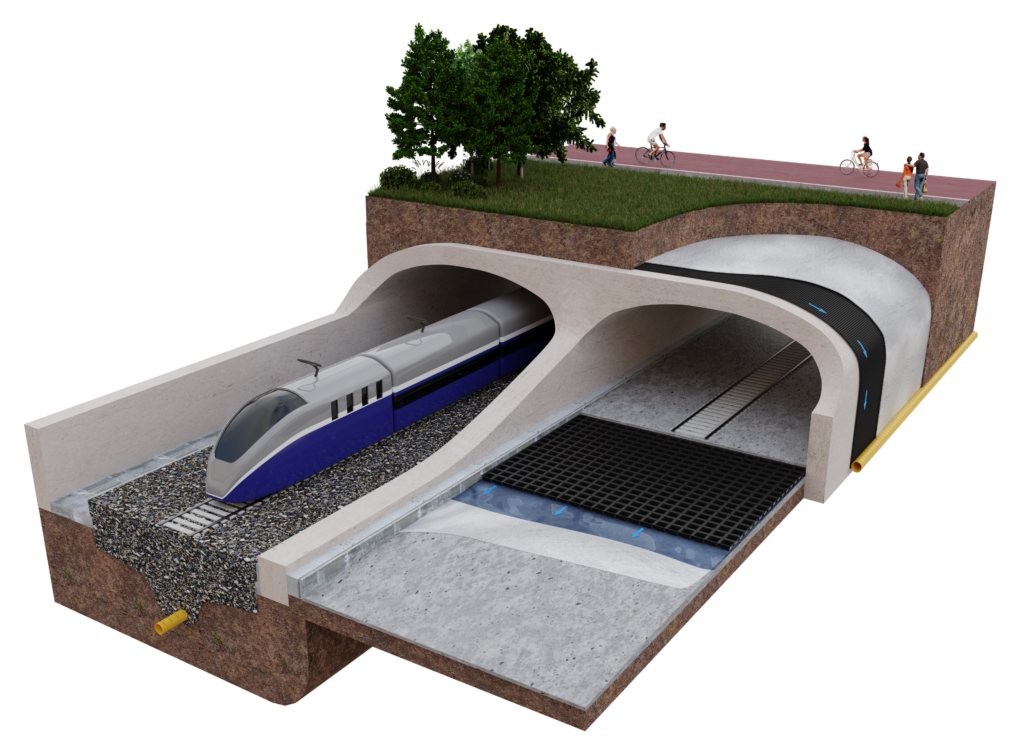

Traditional tunnel invert constructions favour the extensive use of crushed stone together with a longitudinal collection pipe. There is a significant cost in both time and money associated with excavating the trench and crushing and grading the stone before installation. Large quantities of stone are also required to meet drainage requirements.

Cavidrain® Invert provides a pre-formed drainage layer into which the concrete floor slab may be cast and replaces both the invert trench and pipe to collect water from the tunnel invert. Cavidrain® Invert has an in-plane water flow capacity far in excess of crushed stone. Installation is fast and cost effective as excavation and material movement is significantly reduced. The Cavidrain® Invert profile is optimised for maximum bearing area and has been designed to withstand the compressive loads arising from the placement of wet concrete. Once the concrete has cured, the ultimate load capacity of Cavidrain® Invert is that of the concrete infill.

Cavidrain® invert has been used successfully throughout the world in a number of major tunnel projects.

Typical Client Profile

- Tunnel Engineers

- Tunnel Contractors

- Railway Engineers

- Consulting Engineers

- Utility Service Providers

- Waterproofing Contractors