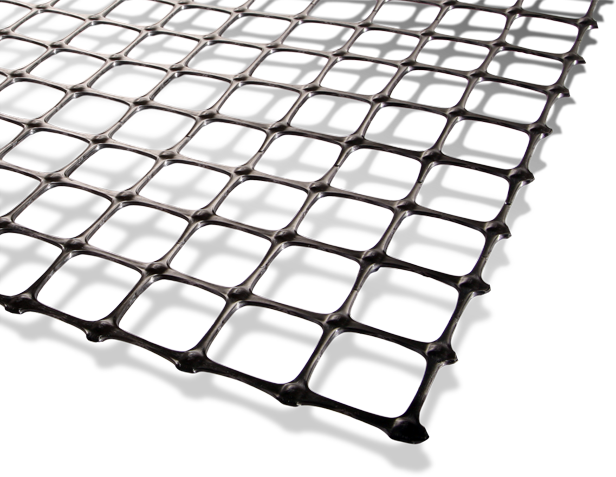

Biaxial geogrid is manufactured from extruded polypropylene which is then punched and drawn to form a monolithic geogrid with strength in two planes (biaxial).

The combination of ribs and the corresponding nodes within the geogrid allows loads to be transferred into the geogrid structure, whilst allowing a positive interlock of the reinforced materials through the apertures of the geogrid.

Biaxial geogrid offers high tensile stiffness at low strains combined with excellent resistance against damage occurring to the geogrid during the construction process or from environmental exposure.

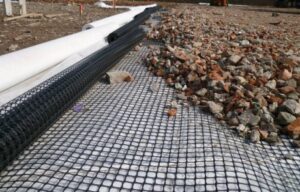

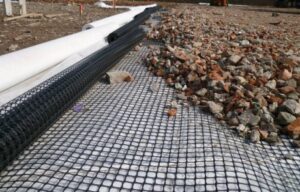

Biaxial geogrid offers savings across the project and is quick and simple to install. The use of biaxial geogrid also facilitates a reduction in the required fill.

Geotexan’s geogrid ranges provide a stabilisation design solution according to the national highways standards and options for improvement of the subgrade include excavation and replacing between 500 to 1,000 mm of the soft subgrade with granular fill, mechanical stabilisation (geogrids and/or geotextiles) and soil stabilisation.

Geotexan can design a stabilised foundation solution to compensate for lower CBR strength values (i.e. less than 2.5%) and achieve the foundation class requirements. The design for all foundation areas shall be based on achieving a foundation class according to the national standard.

Typical Client Profile

- Highway Engineers & Contractors

- Highways Authorities

- Airport Engineers

- Local Authority Planning Depts

- Roofing consultants & contractors