Nonwoven needle-punched geotextiles designed to provide superior protection and drainage capabilities. This range is optimised for increased thickness and elongation compared to standard needle-punched nonwovens, making it well-suited for applications where a thick cushioning layer and high elongation are crucial.

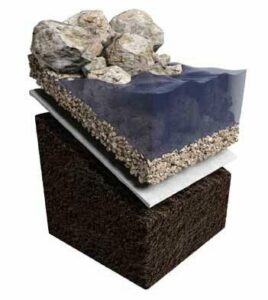

Its typical use is as an erosion control layer under rock armor in coastal defense projects, and acting as a protective cushion layer in landfills and reservoirs. Due to its elevated thickness the range offers higher water flow in the plane values compared to standard needle-punched nonwovens, allowing it to function as a drainage layer in specific applications.

Technical details include tensile strengths ranging from 20 kN/m to 100 kN/m, elongations of 80% or higher, weights from 300 to 1500 g/m², fabric thicknesses up to 10 mm, and CBR puncture values up to 20 kN. Produced using 100% virgin polypropylene staple fibers, Protec also accommodates project-specific dimensions upon request.

Functions include protection, separation, and filtration. Additionally, a flame-retardant version is available, well-suited for protection and drainage applications where there is a high risk of exposure to flames, such as tunnels.

The nonwoven protection geotextiles are engineered to provide unrivalled CBR puncture resistance and tensile strength, offering maximum protection at optimum cost levels.